The Switch Sleeper Marking Robot is an automated identification and precision spraying device integrated into a robotic system. It is designed to automatically mark critical information—such as model type, location number, and installation sequence—onto railway switch sleepers (i.e., switch ties) in turnout areas. Essentially functioning as a mobile, intelligent “industrial spray coder,” it upgrades the traditional process—which relied on manual measurement and handwritten marking—to a fully automated, high-precision digital operation. This addresses the challenges posed by the complex arrangement of switch sleepers and the high error rate associated with manual marking.

1.Fully automatic walking, measuring, and marking operations with one-button control for convenience and efficiency.

2.Equipped with high-precision sensors for fast response and high accuracy.

3.Built-in LED lighting for easy operation at night

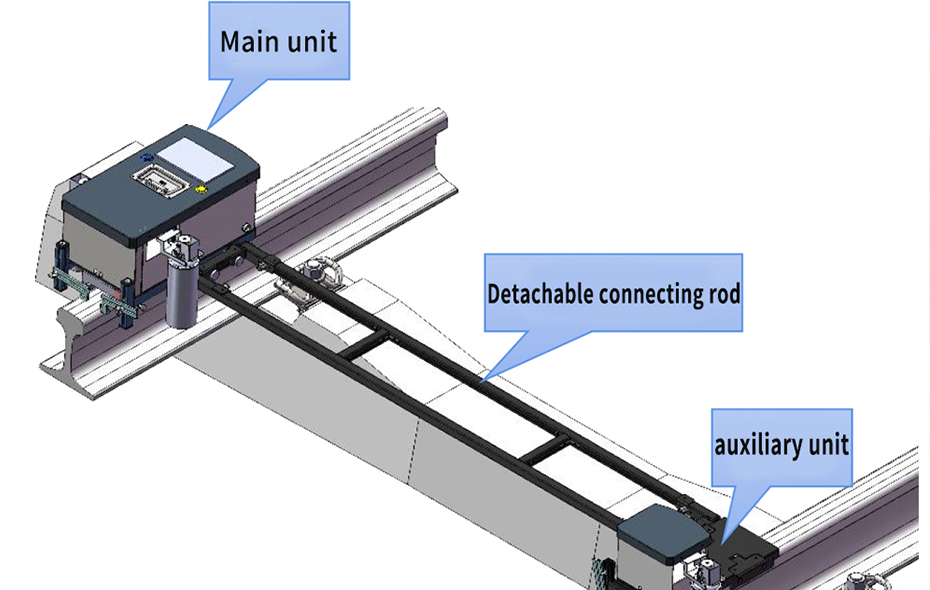

Dimensions | ≤ 18kg, 1800×400×250mm |

Power Supply | Lithium battery, continuous operation time exceeding 6 hours, |

Battery Capacity | 24V 6Ah |

Mobility | The equipment automatically moves along dual rails after the user sets the movement distance |

Printing Spacing | Printing point spacing can be preset during operation (400-800mm, continuously adjustable) |

Speed | Continuously adjustable from 0 to 5 km/h |

Printing Method | Dual-rail multi-side printing |

Printing Time | ≤5 seconds |

Printing Position | Automatic calculation of printing position, with accurate positioning |

Applicable Rails | Suitable for 50kg and 60kg rails |

Working Environment | Suitable for daytime, nighttime, and complex environments such as bridges and tunnels |