The purpose of repairing and maintaining steel rail is to ensure the geometric dimensions of the steel rail. During the operation of the train, the impact force on the steel rail is very large, and it is easy to cause the deformation of the steel rail. Therefore, if you want to enhance the maintenance and maintenance of the steel rail, it is necessary to strengthen the adjustment of the geometric size of the steel rail.

The steel rail track spans different areas, and the gaps at the joints will change at different levels due to the influence of the temperature in different areas. Therefore, each link component must be oiled every year to ensure that it will not be corroded by the external environment. In addition, due to the large temperature difference between winter and summer, in order to ensure that the steel rail track adheres to a suitable range of steel rail joints, the steel rail should be re-inspected twice in the spring and autumn to ensure that the link components of the steel rail joint have been working within the specified range.

The subgrade is an important part of the railway track line. During its long-term operation, it is easy to show the phenomenon of subgrade subsidence, which seriously affects the structure of the steel rail track. Slope protection and drainage measures are regularly checked to ensure the stability of the roadbed.

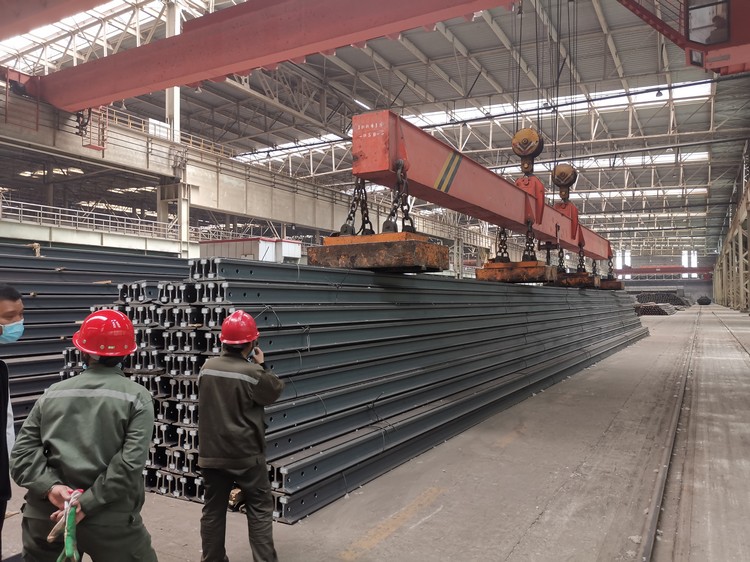

Sleepers and steel rail plays an important part in the railway track, and the steel rail receive a large load during the operation of the railway. In order to reduce the maintenance workload and ensure the smoothness of the track, it is necessary to replace the failed sleepers and steel rail in time.