How Much Pressure Does The Concrete Sleeper Bear?

Concrete sleeper can be used to make wooden sleepers in many types of wood. Wooden sleepers are rich in toughness and can absorb the weight generated by trains better than other sleepers and are not easy to break. Good elasticity, light weight, simple production and good insulation performance. Fasteners and wooden sleepers are simple to connect, convenient for laying, maintenance, and transportation. There is a large friction coefficient between wooden sleepers and gravel ballast.

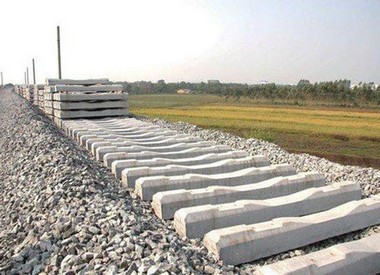

Concrete sleepers have high rigidity and poor elasticity, resulting in greater pressure and vibration on the ballast bed, resulting in faster pulverization of the ballast, which can easily cause the track to sink. Therefore, it is necessary to use tough ballast and add an elastic cushion. Reinforced concrete sleepers are much heavier than wooden sleepers and are not suitable for use on newly filled subgrades or unstable subgrades. Compared with wooden sleepers, it does not consume wood, has a longer service life, higher stability, easier maintenance, and lower damage rate and scrap rate. On the seamless track, the stability of reinforced concrete sleepers is 15-20% higher than that of wooden sleepers on average, which is especially suitable for high-speed passenger lines.

What Is The Scope Of Application Of Concrete Sleeper?

The concrete sleeper are divided into S series and J series by different reinforcement, and are divided into I, II, and III by the load capacity, and the load capacity increases sequentially. The specification model is marked on the surface of one end of the sleeper. Concrete wide sleepers: Also known as sleeper slabs, the width is generally twice that of ordinary sleepers. The advantage is to enhance the lateral stability of the track.

Compared with wooden sleepers, it does not consume wood, has a longer service life, higher stability, easier maintenance, and lower damage rate and scrap rate. On the seamless track, the stability of reinforced concrete sleepers is 15-20% higher than that of wooden sleepers on average, which is especially suitable for high-speed passenger lines. The high rigidity and poor elasticity result in greater pressure and vibration on the ballast bed, resulting in faster pulverization of the ballast, which can easily cause the track to sink. Therefore, it is necessary to use tough ballast and add an elastic cushion. Reinforced concrete sleepers are much heavier than wooden sleepers and are not suitable for use on newly filled subgrades or unstable subgrades.

Calculation Of The Spacing Of Concrete Sleeper?

The spacing of concrete sleepers is related to the number of sleepers per kilometer. The latter should be determined according to the transportation volume, driving speed and line equipment conditions, and comprehensive consideration of steel rails and track beds, etc., and reasonable matching, in order to ensure the track under economic conditions Has sufficient strength and stability.

The concrete sleeper are denser, and the stress on the track bed, subgrade surface, steel rail and sleeper itself can be smaller. At the same time, it is easy to maintain the gauge and direction, which is especially important for areas with high driving speeds. But it should not be too dense. Too dense is not economical, and if the clear distance is too small, it will also affect the tamping quality to a certain extent. According to China’s railway regulations, the number of wooden sleepers per kilometer is 1920, and the number of concrete sleepers is 1,840; the minimum is 1440 per kilometer. The level difference of sleepers is 80 per kilometer. The number of laying per kilometer is determined by the line level. For the main track, it can be selected according to the "main track type" table.

For sections that meet one of the following conditions, the off-line track should be strengthened. In addition to the number of sleepers per kilometer listed in Table 1-15, there will be an increase of 80 concrete sleepers per kilometer and 160 wooden sleepers. When the conditions overlap, Only increase once, but cannot exceed the aforementioned allowable laying amount.