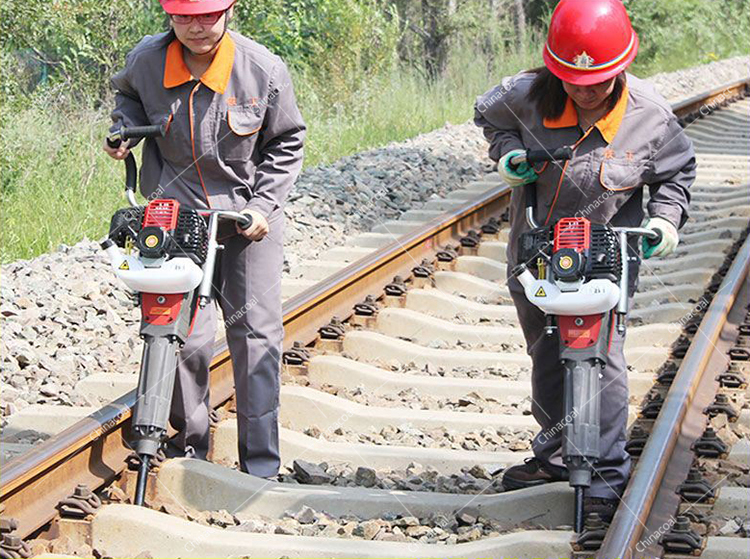

The ND-4.2X2 internal combustion high-frequency railway tamping machine is a new type of railway maintenance machinery, which is suitable for the maintenance and construction of unilateral railway lines without power supply, and can also be used for the maintenance of turnouts.

Railway Internal Combustion Railway Tamping Machine Preparation And Start-Up Work

1. In accordance with the Honda gasoline engine user manual and instruction manual, strictly conduct various inspections before operation. Please use unleaded gasoline of No. 90 or higher. Use SAE10W-30 engine lubricating oil (SG.SF category) at common temperatures.

2. Rotate the connecting handle on the railway tamping machine head directly above, insert the flexible shaft plug into the shaft inner hole, insert the connecting head into the machine head hole, make the connecting handle fall into the arc groove of the connecting head, and connect the handle under the board. Insert the vibrator on the rack.

3. Check all railway tamping machine insulation parts, tighten all fasteners, and tension the transmission belt.

The above is the preparation and start-up details of the internal combustion railway tamping machine I have introduced to you. I will continue to share with you more methods and knowledge of railway tamping machine usage. If you are interested, please leave a message with us!